1. Introduction: Supervision means overseeing a process and making sure it works well. To do this, a supervisory system collects, monitors, and records important data about the process to detect any issues and alert the operator. The main goal of a supervisory system is to help the operator control and manage an automated process. Supervising industrial processes involves tasks that ensure the process is controlled and works properly.

A SCADA system helps supervise, control, optimize, and manage systems for power generation and transmission. The key part of these systems is RTUs (Remote Terminal Units), which automatically collect data and are connected to sensors, meters, or equipment. RTUs are placed close to the process and send data to the controller when needed. They often include software, data storage, a real-time clock, and battery backup. Many RTUs have backup systems in case the primary unit fails. PLCs (Programmable Logic Controllers) can also monitor meter readings and equipment status.

2. Hydropower Plants Automation: Before automation, qualified workers operate equipment manually. This was called the Manual System. To operate the hydropower plant equipment, such as turbines, generators, and breakers, the operators first had to check the condition of the equipment. Based on this, they would make necessary adjustments to fix any problems. This method required constant supervision by the operators.

The automatic system works similarly, but it automatically checks the equipment’s status and sends commands to control the power plant equipment. It also manages auto-sequencing of operations. However, even with automation, specialized personnel are still needed. Operators must monitor the system and make adjustments to the controls when needed, depending on production requirements. A system for managing, controlling, and protecting the operation of a hydropower plant is designed by gathering real-time information, offering local and remote control capabilities, and providing advanced protection features. This automation system includes:

- Excitation & Generator Protection

- Turbine Control

- Substation Control

- Synchronizing

- SCADA

3. SCADA System for Hydropower Station: SCADA stands for Supervisory Control and Data Acquisition, which refers to computer systems used to monitor and control industrial processes. A SCADA control center allows centralized monitoring and control of field sites over long-distance communication networks. It helps with monitoring alarms and processing the status of the systems. For plant control and data collection, SCADA systems are often combined with PLC (Programmable Logic Controller) controllers and PC-based systems. This setup is cost-effective, making it suitable for small hydroelectric power plants for generation, control, and automation. Based on the information received from remote stations, the system can send automated or operator-driven commands to control devices, often called field devices.

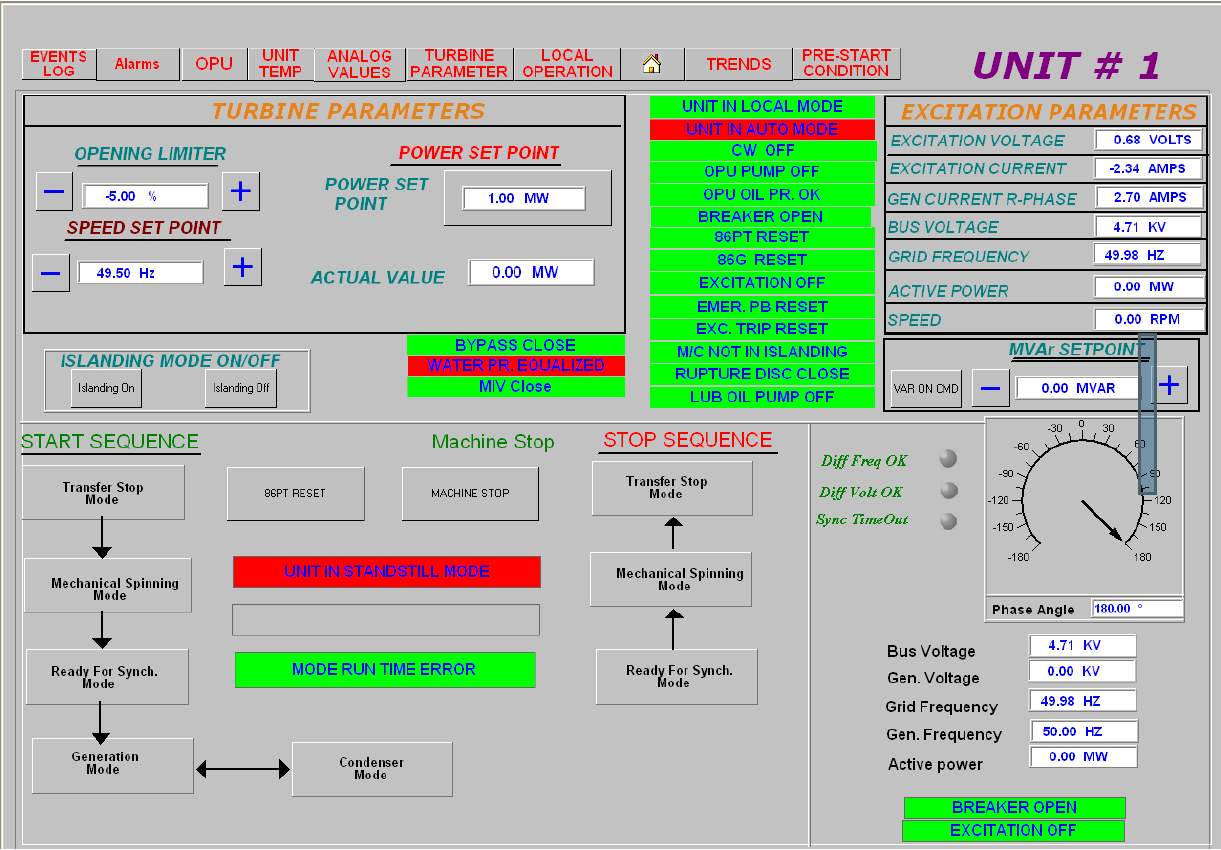

A typical SCADA system in a hydropower plant is divided into several sections for operation and monitoring, as shown in Figure 1. These sections include:

Section 1: Turbine Parameters: Here, the operator can monitor and adjust turbine parameters.

Section 2: Status Display: This section shows the status of the machine.

Section 3: Excitation Parameters: In this section, the operator can monitor the analog values of key excitation parameters.

Section 4: Command Section: This is where operators issue start and stop commands for the machine.

Section 5: Synchronizing Section: This section allows the operator to monitor the synchronization condition of the machine and related electrical parameters.

Additional requirements for the system operator include:

- A probabilistic approach for network management.

- Control of centralized units.

- A compensation plan for voltage regulation.

4. Conclusion: In conclusion, the SCADA (Supervisory Control and Data Acquisition) system plays a vital role in monitoring and controlling various processes within a hydroelectric power plant, particularly when managing operations from remote locations. SCADA enables operators to make critical set-point adjustments on remote controllers, open or close valves and switches, monitor alarms, and collect data from local instruments that are part of a broader, distributed system. This real-time control capability ensures that the system operates smoothly and efficiently. The use of SCADA in a hydropower plant transforms the way operators interact with the process, providing a virtual environment where control responses can be quickly adjusted to maintain optimal performance. It helps ensure the plant’s systems are functioning as intended, reducing downtime and improving overall plant efficiency.