Choosing the right power cable is crucial whether you're wiring a home, office, or industrial setup. Power cables ensure the safe and efficient flow of electricity, and selecting the correct type and size can prevent potential issues like overheating, voltage drops, or system failures. In this article, we’ll guide you through the process of selecting the right power cable for both residential and industrial purposes. In this post, we’ll go over two easy methods for selecting cable sizes, with a focus on practical use in 3-phase systems.

📗 Why Proper Cable Sizing is Important

- Safety: Choosing the wrong cable can lead to overheating, short circuits, or even fires. A correctly sized cable ensures that electricity flows safely without excess heat buildup.

- Efficiency: A well-chosen cable prevents energy loss and voltage drops, ensuring that appliances and machinery receive a steady and adequate power supply.

- Cost Savings: Using the right cable size can help avoid overspending on unnecessary thick cables or costly future repairs if the cables are undersized.

📗Factors to Consider When Choosing Power Cables

1. Type of Load (Residential vs. Industrial)

- Residential Load: Residential buildings typically have a lower power demand compared to industrial setups. For homes, the cables used are usually designed to handle smaller loads, such as lighting, heating, and small appliances.

- Industrial Load: Industrial environments, on the other hand, require cables that can handle high-voltage machinery, heavy equipment, and continuous power supply. The cables must have a higher current-carrying capacity and be durable to withstand extreme conditions.

2. Cable Material (Copper vs. Aluminum)

- Copper Cables: Copper is a better conductor of electricity and is commonly used in residential and high-performance industrial applications. While copper cables are more expensive, they are more efficient and provide better conductivity.

- Aluminum Cables: Aluminum cables are lighter and less expensive but not as efficient as copper. However, they can be suitable for lower-load residential applications or where the cable length is short.

3. Cable Insulation (PVC, XLPE, etc.)

The insulation of the cable determines its ability to withstand environmental conditions, heat, and potential damage. Common insulation types include:

- PVC (Polyvinyl Chloride): PVC is the most common insulation for residential and commercial cables. It is inexpensive and provides good protection against moisture and mild temperature variations.

- XLPE (Cross-linked Polyethylene): XLPE is used for cables that need to endure higher temperatures and more demanding environments, such as industrial settings. It offers superior electrical and thermal performance.

4. Voltage Rating

Power cables are designed for specific voltage levels. It’s important to match the cable’s voltage rating to the system you are installing.

- For Homes: Most residential electrical systems use 230V for single-phase and 400V for 3-phase systems. Ensure that the cable voltage rating matches or exceeds the voltage requirement of your home system.

- For Industry: Industrial systems often require higher voltage levels, ranging from 415V to several kilovolts for heavy machinery and large installations. Industrial cables must be rated accordingly to handle these higher voltages.

5. Current Carrying Capacity (Ampacity)

The ampacity of a cable refers to its ability to carry electrical current without overheating. It is directly related to the cable’s size (thickness) and material. The higher the current a system needs, the larger and more robust the cable must be.

- For Homes: You might need cables with a capacity to handle 10 to 60 amps for typical appliances and lighting.

- For Industry: Industrial cables may need to handle hundreds of amps for large equipment, motors, or high-load machines.

👉How to Calculate the Right Cable Size

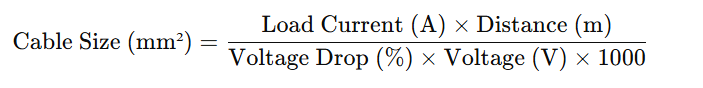

1. Formula for Voltage Drop-Based Calculation

When transmitting power over a distance, the voltage at the load end can drop. This is particularly important when cables are long. The voltage drop should be within acceptable limits to ensure proper system performance.

Formula:

- Load Current (A): The current drawn by the load (in amperes).

- Distance (m): The length of the cable run (in meters).

- Voltage Drop (%): The allowable percentage of voltage drop (usually 3% or less).

- Voltage (V): The system voltage (e.g., 230V for residential or 400V for industrial systems).

Example: We will use the voltage drop-based calculation formula:

Given:

- Load Current (I): 350A

- Voltage (V): 400V

- Cable Length (L): 150m

- Allowable Voltage Drop: 5%

Cable Size (mm²) = Load Current (A)×Distance (m) / Voltage Drop (%)×Voltage (V)×1000

Substituting the values:

Cable Size (mm²) = 350×150 / 5%×400×1000

Cable Size (mm²) = 52,500 / 20,000 = 240 mm²

So 5% voltage drop, the cable size would be approximately 240 mm².

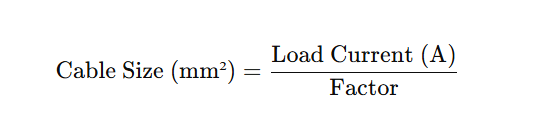

2. Formula for Load Current-Based Calculation

This is a simpler, quick method for estimating the cable size based on load current. It’s particularly useful in the initial design phase or for smaller residential loads.

Formula:

- For 3-phase systems: Use a factor of 2.5.

- For 1-phase systems: Use a factor of 1.5.